M360 is a new generation four side moulder developed by SAGAMAC-a very affordable machine with innovative design

Categories: Four side planer moulder

| The story for M360:

For 5 years, we are planing to make a moulder which can do big width planing and moulding work, and machine better easy to set, finally it should be affordable on price, traditional 4 side mouler horizontal spindle tail not lock, so it got chance to vibrate when do very big width, even we can add hydro lock at tail this will makes price too high, so better the 2 tail is fixed by bearing, indeed some machine like thickness planer aready exist this type of design, just we need make sure the feeding table so stable enough to hold the 2 vertical spindle and same time can simplely adjust the width, and for different thickness setting, there are 2 way to acheive, model 1 is to raise or down top spindle, model 2 is to raise or down table, first model need very complex design and it back to traditional idea which need to make machine at lest 4 time heavy and make cost no reasonable, so we chose model 2, but this model all machine allover the world don’t got initial table micro adjust to acheive different planing amount, we also meet this problem(to be sincere, we refference to some international similar machine), because the extra attached table should install on the machine table and it go up and down with it, same time need to adjust the initial table and make sure the extra attached table also go together with initial table, thus we combined both simple design to acheive very thick planing ability like thickness planer, but also got initial table adjustment like a joint surface planer, and this design have becomed a paten design of SAGAMAC and finally end the tedious change of different thickness plate to achive planing amount. This problem solved and next is the stable life long running, we aim to make it easy to transport or even with rollers to shift but also make sure the machine can do tough planing and moulding work, thus we invest 2 month time to rectify the design of inner body to make sure all is logic with strength and precision and finally our machine can Optionally intall max 7.5kW 10hp power to do same work like any heavy duty industrial moulder. Whe the machine come out and we test it with large log and T and G moulding, it both durable for heavy extremely 5mm planing amount work on Oak wood, but also can feeding very thick and wide material smooth like a 200 by 200mm log, it is a good feeling that we can help our customer to meet challenge to any innovative moulding design but also we can make the cost of machine affordable. I think this is same to any world class great design-let more people to enjoy the affordable innovative design and we want to say here: You are also engineer!

|

|

M360 is a extremely heavy duty model compare with international similar models, with industrial 40mmertical spindle max optional 7.5kW up to 10Hp spindle power, can do max 50mm depth side moulding work, rather than use light duty motor direct motor spindle, we use industrial professional V belt driven extra spindle which is same design to any international heavy industrial moulder. The horizontal spindle got professional reference line for tools install and diameter of spindle up to 98mm, can do max 20mm moulding depth.The max planing width at double side model can reaches up to extremely 400mm, and 4 side planing or moulding up to 360mm, max planing height up to 200mm.

M360 makes you confidence to meet any challenge moulding work, start with M360, start your own creative design with spirit of engineer.

|

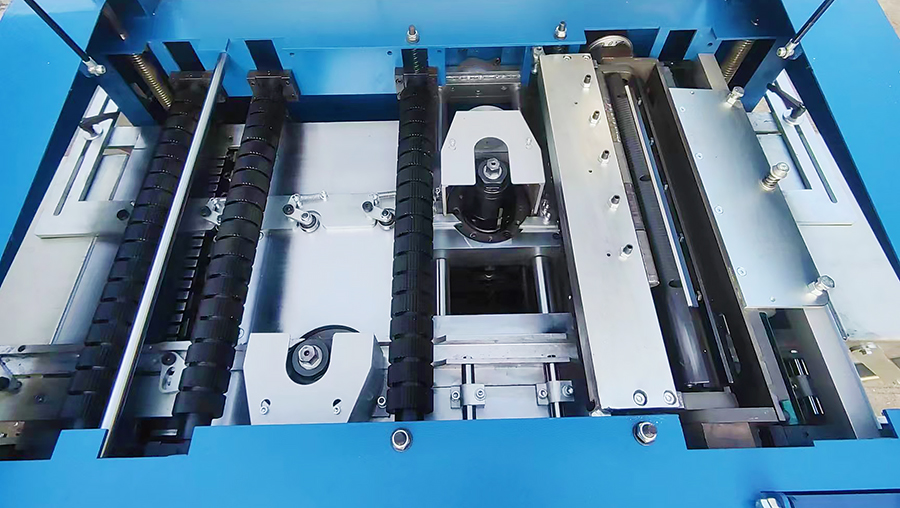

| The solid heavy duty design of mechanical system is key point for a high precision and heavy duty planing and moulding work, with Sharpen teeth feeding roller at initial and durable rubber roller at final, can gives both powerful and smooth feeding, whole tables is hard chrome treated for life long smooth feeding and unti-rust. Optional helical spiral cutter for horizontal spindle both for bottom and top. Professional top cutter until jump system is a unique design of SAGA M360, it help to make a very smooth planing work and effectively prevent over plan, when do moulding work, the unti jump system can take off for more deep moulding work. |

|

|

|

|

Initial table micro adjustment easy to get precise planing amount without tedious change of different thickenss plate |

Professional top spindle unti jump system avoide from over plan, also can be taken off if shaper cutter tips is used |

|

|

|

|

Linear guiding rail to guid the raise and down of table to make sure the table is in good alignments |

Micro adjust thick knob with number indicates the micro adjust amount for highest precision thickness setting |

|

|

|

|

Industrial 40mm industrial spindle |

Hard chrome treated feeding table and plate for spindle |

|

|

|

|

Gavanized extra feeding and outlet table |

Optical windows on dust collection |

Heavy duty structure makes whole machine works very stable, whole machine after installation weight up to 1100kgs

About Us

© 2024 by SAGA Machinery Co.,Ltd All rights reserved Privacy Policy